Our Production Process

The cotton is processed using the industry’s most advanced machinery that uses bare minimum manual intervention. The advanced machinery such as a clearer that ensure’s 1 00% defect free cotton and comber machine’s delivering the most superior quality yarn.

The yarn is then transformed to fabric in the knitting machine personifies technological advancement and can knit all types of knitted fabrics

The knitted Fabrics are dyed in a modern dye house with HTHP soft flow machines to process both cotton and blended fabrics like 100% cotton Fabric, cotton + polyester - Blended Fabric , cotton + viscose - Blended Fabric , viscose + polyester - Blended Fabric ,Cotton + Modal - Blended Fabric .

The Dyed Fabric passed through the compacting machine at a specific heat temperature with fast feeding, beating, and slow delivery technology will provide the fabric with a uniform weight, control shrinkage, avoid spirality, and provide an excellent uniform feeling.

Printing is a key area for leaving a lasting impression. Continuous Printing machine print the Programmed design to the entire Length of the Fabric roll without gap. This printing systems offer our customers a range of print options.

We can do any kind of printing including Plastisol print, reflective printing, pigment printing, Puff printing, Embossed printing, Heat transfer sticker printing, high-density printing etc. This Placement printing systems offer our customers a wide range of print options.

The multi Head

computerised Embroidery

machine make it possible

to design

embellishments, motifs

and logo designs on the

garments with 100%

accuracy and defect free.

This value addition enable

us to conquer high fashion

and at competitive price.

We are proud to offer you a

unique collection of vibrant

colours for embroidery.

The key to producing fine garments lies in cutting. . Very intricate shapes can be cut by BAND knife cutting machines.

Sewing to make any style with different fabric structure. These high speed machines with latest attachments helps us in making high fashion garments within stipulated time and with right Quality

Each Garment checked thoroughly in the aspect of Quality of sewing, small handling defects, make up and trims by an expertise and experienced checkers to meet the quality standard.

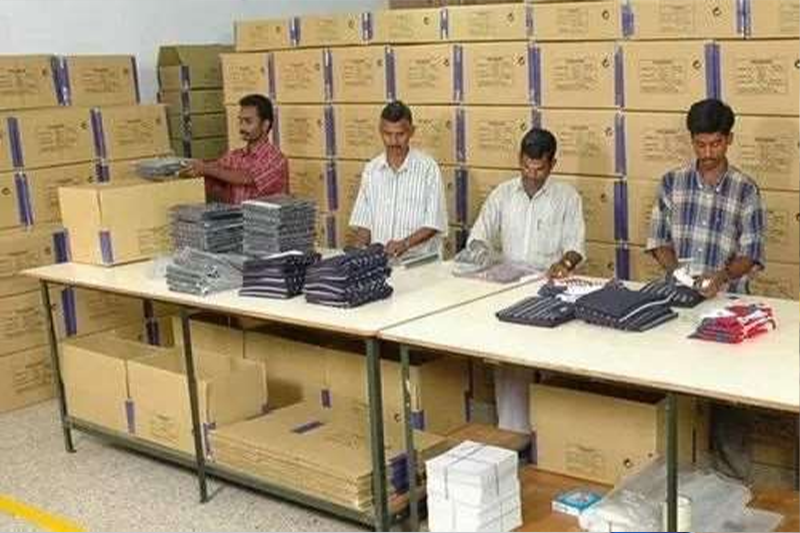

Finishing line consists of vacuum tables with steam presses to give the final touch to the garments and make sure they are packed as per the ratio and method defined by the customers in prestine condition.

Finished Garments neatly folded and packed in An individual polybag

Approximately 60-80 Pieces packed in one Seaworthy Export carton suitable for Long Distance Transportation

Celebrating over three decades of expertly crafting premium T-shirts.